Introduction

Photovoltaic (PV) cables play a crucial role in connecting solar panels to the inverter and other components of a solar power system. As such, the reliability and longevity of PV cables are essential for the overall performance and efficiency of a solar energy system. One of the key challenges faced by PV cables is corrosion, which can significantly impact their functionality and lifespan. In this article, we will explore the importance of corrosion resistance in PV cables, the factors contributing to corrosion, and strategies to enhance corrosion resistance for improved performance and durability.

Importance of Corrosion Resistance in PV Cables

Corrosion is a natural process that occurs when metals are exposed to environmental factors such as moisture, humidity, salt, and chemicals. In the case of PV cables, corrosion can occur on the conductors, connectors, and other metal components, leading to a range of issues including increased resistance, voltage drop, and even system failure. Therefore, ensuring corrosion resistance in PV cables is essential to maintain the efficiency and reliability of the solar power system.

Factors Contributing to Corrosion in PV Cables

Several factors contribute to the corrosion of PV cables, including environmental conditions, material selection, and installation practices. Rubber Sheathed Cable as high humidity, salt spray, and exposure to chemicals can accelerate the corrosion process. Additionally, poor material selection, such as using metals that are not corrosion-resistant, can also lead to premature degradation of PV cables. Improper installation practices, such as inadequate sealing of connectors or exposure to moisture during installation, can further exacerbate corrosion issues in PV cables.

Strategies to Enhance Corrosion Resistance in PV Cables

To improve the corrosion resistance of PV cables and ensure their long-term performance, various strategies can be implemented. These strategies include the use of corrosion-resistant materials, proper installation techniques, and regular maintenance and inspection.

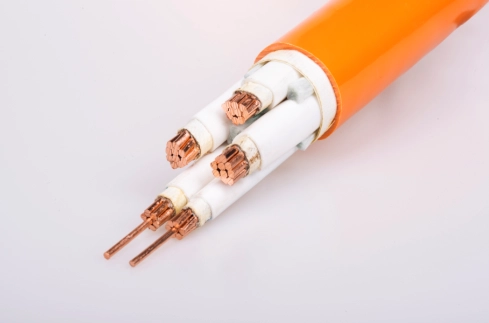

1. Corrosion-Resistant Materials: Selecting materials that are inherently resistant to corrosion is key to enhancing the longevity of PV cables. Copper conductors with a corrosion-resistant coating, such as tin or silver plating, can help mitigate the effects of corrosion. Similarly, using stainless steel or aluminum connectors with appropriate coatings can also improve the overall corrosion resistance of PV cables.

2. Proper Installation Techniques: Proper installation practices are crucial in preventing moisture ingress and reducing exposure to corrosive elements. Sealants and weatherproofing materials should be used to protect connectors and cable joints from moisture and environmental contaminants. Additionally, ensuring that cables are properly secured and protected from physical damage can help prevent corrosion-related issues.

3. Regular Maintenance and Inspection: Conducting regular maintenance and inspections of PV cables can help identify early signs of corrosion and address them before they escalate. Periodic cleaning, testing, and visual inspections of cable connections and exposed metal surfaces can help prevent corrosion-related failures and ensure the long-term performance of the solar power system.

Case Studies and Best Practices

Several case studies and best practices demonstrate the importance of corrosion resistance in PV cables and highlight effective strategies for enhancing durability and performance. For example, a study conducted by a leading solar installation company found that implementing proper sealing techniques and using corrosion-resistant materials significantly reduced the incidence of corrosion-related failures in PV cables. Similarly, best practices recommended by industry experts emphasize the importance of regular maintenance, proper installation, and material selection to mitigate corrosion risks in solar power systems.

Conclusion

In conclusion, corrosion resistance is a critical factor in ensuring the performance and longevity of PV cables in solar power systems. By implementing strategies such as using corrosion-resistant materials, proper installation techniques, and regular maintenance and inspection, the impact of corrosion on PV cables can be minimized, leading to improved efficiency and reliability of solar energy systems. As the demand for renewable energy continues to grow, enhancing the corrosion resistance of PV cables will be essential to maximizing the potential of solar power generation and promoting sustainable development.